There is not really a fixed order in which to route things, but before routing, footprint placement is an extremely important step.

Quite often, instead of using “zero ohm” resistors, you can also use real resistors that are already in your design to double up to jump over something else by moving them to the right position.

Routing the PCB is also an iterative process. For example from the lower right corner of your screenshot, you can easily get rid of two via’s by rerouting the blue part on the red layer as I did here in green:

And such things can be done quite often.

I also noticed that your tracks are quite thin. Probably the default, and that is a bit too thin to my liking, but to be sure, you first have to select a PCB manufacturer, and look at the design rules on their website, and make sure you setup coarser design rules in KiCad. Coarser design rules can often lead to a less expensive PCB. And design rules is not only track width and clearance, but also via drill sizes, annular ring sizes and some more.

Also, while routing, and you notice you have to go over/under another track, don’t regard that other track as an immovable obstacle. That other track can often be rerouted in some other way, so it does not form an obstruction anymore.

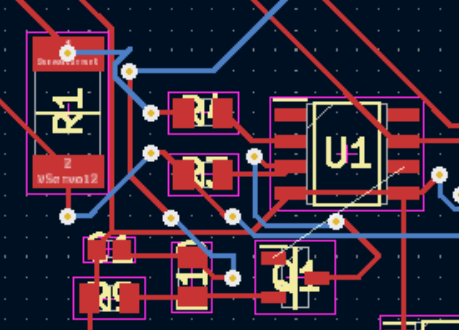

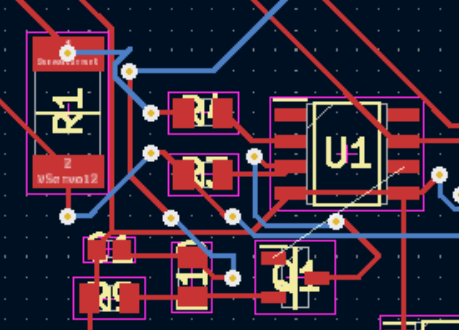

When you see a lot of layer changes in a small area:

Then often such area’s can be optimized a lot by re-routing the tracks, or by just rotating or moving a footprint.

Some people are annoyed that an “auto router” does not “automatically route” a whole PCB, and they are not finished yet after drawing a schematic, but making a good PCB layout is an art in itself, and it 's much more involved than just routing some wires. For example if you have a 10MOhm resistor, it can matter a lot if the “long track” is on the left or on the right pad of that resistor, and auto routers do not know such things. Placement of decoupling capacitors is also critical and there are many more factors to keep in mind during footprint placement and routing.

Reading about what things are important in a good design helps, but you also have to build experience by doing it. Treat it as a puzzle that is more fun then sudoku (I hate those useless games), but when you’ve routed a PCB nicely, you’ve got a real product that can be manufactured instead of a piece of paper full with scribbles that’s ripe for the garbage bin.