As far as I know KiCad does indeed not support arc’s in tracks (yet).

What is supported is drawing arc’s on non-copper layers, and making pads from graphic items in the footprint editor.

Super mini tutorial.

1). Open the footprint Editor.

Footprint editor / File / New Library / (Enter name) / [Enter] / Add to Project libary table.

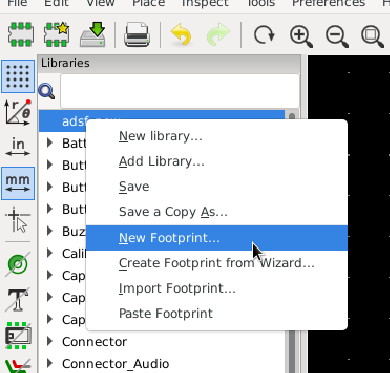

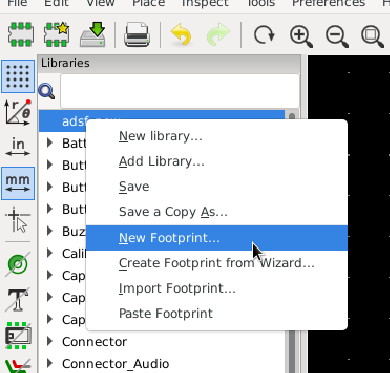

2). Select your new library by double clicking on it, then [RMB] & “New Footprint” from the popup menu:

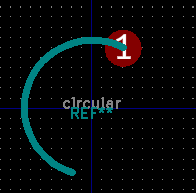

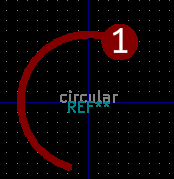

3). In your new footprint in the footprint editor draw something like:

Notes:

- I drew the arc on the silkscreen layer

- You can adjust the widht of the arcs by hovering over them and press ‘e’ to edit.

- It must have an pad which becomes the attachment points for further tracks.

4). Draw a box around your arc and pad, then [RMB] and select "Create Pad from Selected Shapes. Your silkscreen arc has now become part of the pad.

5). If you draw a box from upper left to lower right, then items crossing the box are not part of the selection. However, if you draw the box from lower right to upper left, items crossing the box boundaries are included.

6). You have to repeat this for every arc, and then it becomes difficult to select the next objects for the custom pads. It is a lot easier if you move the custom pads to the other side of the board after drawing, and then hide that layer while drawing the next custom pad. You can select the layer by hovering over a part of the pad and then press ‘e’ for edit, and select another copper layer. You should also remove the ticks for the mask and paste layer, because you do not need these.

7). The next limitation you have to work around is that your circular footprint only has an attachment point on one side. Resolving this in a way that would not generate DRC errors will be difficult, but also not very important on such a relatively simple PCB.

It is possible to draw real arcs this way but you have to work around some limitations in KiCad which make it a bit difficult.

The way Rerouter suggest is also possible, and quicker, but you will not have real arcs, and you indeed have to disable the push and shove of the Interactive Router or it will create a big mess.

Drawing the Arc tracks by hand is a lot more accurate and easier if you first draw circles on the Dwg.User or another “technical” layer, and use those as guidelines to draw your semi-arc track segments.