Mechanical ‘hysteresis’ is from the ‘Backlash’ - in Milling, it’s when the direction reverses and the travel in a ‘Repeating’ manner does Not fully travel to the exact same ‘value’ (if you want to call it that). It’s commonly due to mechanical ‘Slop’ , ‘Wear’…etc.

My Mill (as does most Mill’s) has inherent ‘Backlash’ of some amount, mine has 0.001 to 0.002 Inch of Backlash.

The ‘setup’ has Controller Adjustment/Compensation for it and determining the Setting-Value is based on measuring travel-direction changes in testing (typically at Maintenance time) .

If one were to Plot this, it would look just like most any other Hysteresis

NOTE:

I stopped adjusting Backlash about 10yrs ago after determining that moderate usage always proved out the Backlash grew to about 0.001inch and that is what I set the Compensation to. Yes, I can tighten it up but it’s not important for my projects.

Screenshot is ‘How to test Backlash’

ADDED:

I use LM386 in some Audio projects (I’m also a Musician and fiddle with Stomp-Boxes…)

There’s nothing wrong with using someone’s design but, for me, when it comes to using Chips/parts/etc, I prefer referring to manufacturing Spec’s and starting with their recommended Circuits and building them (on BreadBoards before doing a PCB).

Here’s link to Spec and you can start at page 12 and review the recommended circuit(s) for various Gains/Distortion/Oscillation…

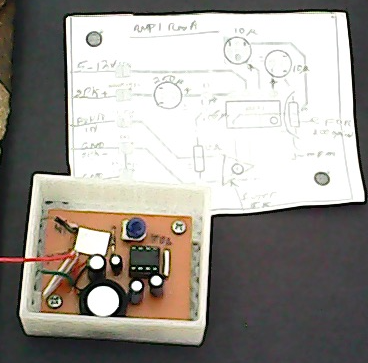

An old photo of my first LM386 test on BreadBoard… and on PCB. I still use them!